Year: 2025

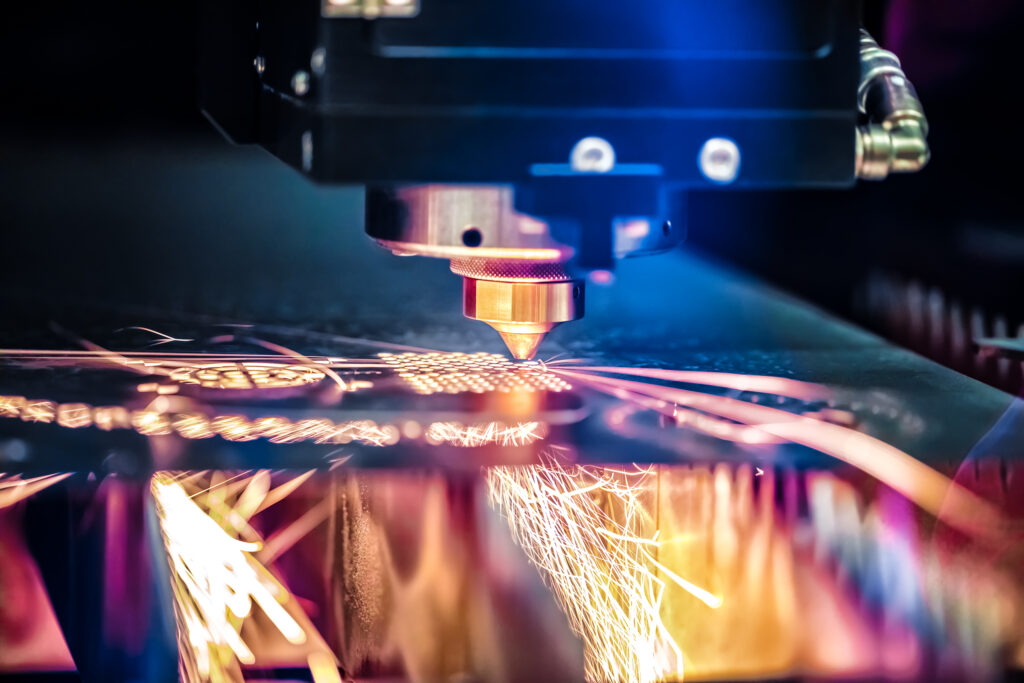

Maximizing Efficiency with Custom Laser Engraving

As manufacturing environments become more automated and quality standards continue to rise, the demand for precise, permanent part marking has…

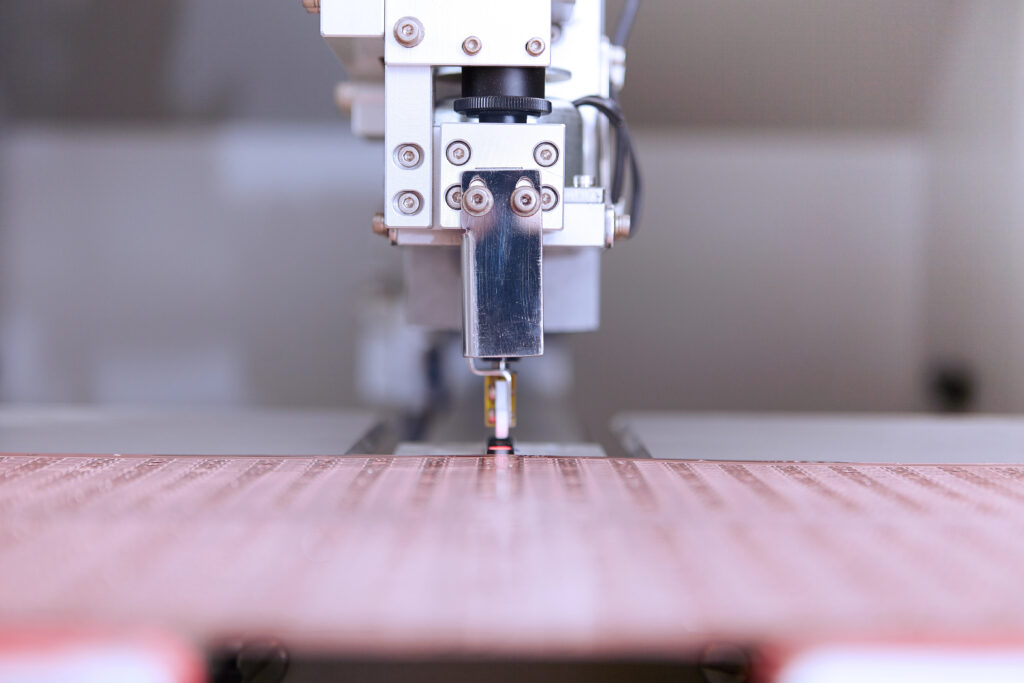

Key Terms Needed To Know About Spiral Binding

At PEL Manufacturing, we specialize in helping businesses, schools, and print shops create professional-looking documents with spiral coil binding. Understanding…

Laser Engraving vs. Traditional Etching: Which Offers Better Accuracy?

In manufacturing, branding, and product identification, precision matters. For decades, traditional etching was the go-to method for marking logos, serial…

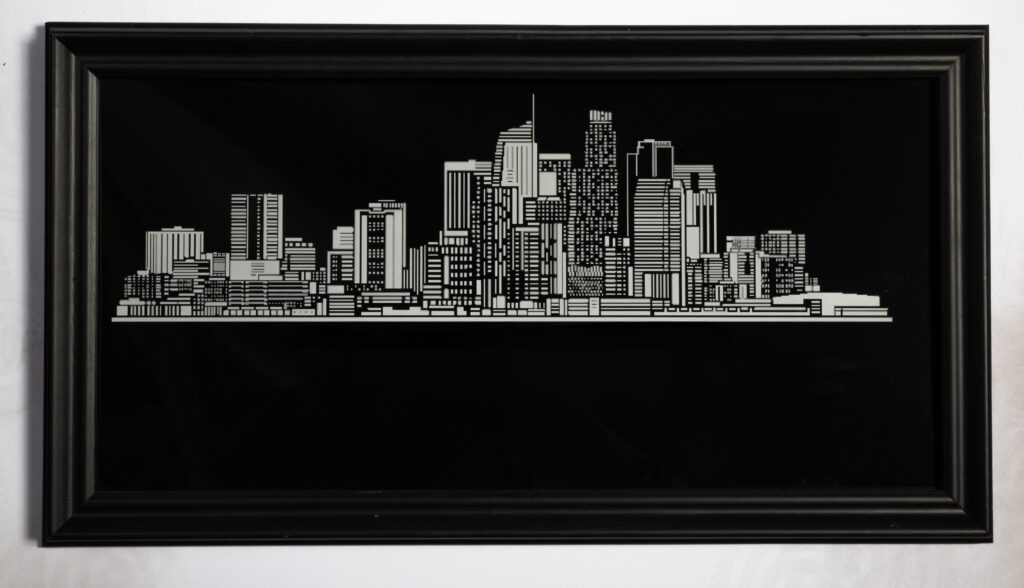

Discover the Precision and Possibilities of Laser Engraving

Personalization has never been more popular, and laser engraving makes it possible to turn everyday items into meaningful keepsakes or…

Nearly a Century of American Manufacturing Excellence

A Legacy of Craftsmanship Since 1934 When the Pelezzare family founded PEL Manufacturing in 1934, they set the foundation for…

Designers Love Colorful Spiral Coils—And It’s Not Just for Looks

A Touch of Color That Does More Than Pop If you’ve ever held a bold-colored planner, workbook, or presentation and…

The Coolest Things You Can Get with Laser Engraving in Torrance

Not Just Trophies and Nameplates: Laser Engraving in Torrance Has Gone Next Level If the phrase laser engraving in Torrance…

Looking for a Unique Gift? Why Laser Engraving Is the Way to Go

We’ve all been there—scrolling endlessly for a gift that doesn’t feel like an afterthought. Whether it’s for a birthday, anniversary,…

Looking for a Unique Gift? Why Laser Engraving Is the Way to Go

We’ve all been there—scrolling endlessly for a gift that doesn’t feel like an afterthought. Whether it’s for a birthday, anniversary,…

Why Custom Printing Gives Small Businesses a Big Brand Boost

Standing out in a crowded market isn’t easy—but custom printing helps When you’re running a small business, it can feel…