Laser engraving is one of the most versatile customization methods available today. From corporate awards and branded merchandise to personalized gifts and industrial labeling, the right material plays a critical role in achieving clean, professional results. Understanding how different materials respond to laser engraving helps ensure durability, clarity, and visual appeal.

If you’re planning a custom project, this guide will help you choose the best surface for your needs.

Wood: Natural and Timeless

Wood remains one of the most popular materials for laser engraving. It offers a warm, organic look and produces high-contrast results when engraved. Hardwoods like maple, walnut, and cherry deliver crisp detail, while softer woods create a deeper, rustic effect.

Wood works well for signage, plaques, keepsakes, and decorative products. If you’re exploring customization options, professional laser engraving services ensure precise settings for consistent results across batches.

Acrylic: Modern and Versatile

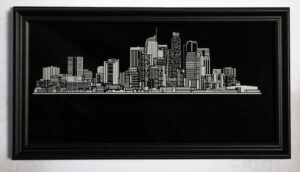

Acrylic is ideal for projects that require a sleek, contemporary appearance. Laser engraving on acrylic creates a frosted, clean finish that stands out beautifully on clear or colored sheets.

It’s commonly used for awards, branded displays, nameplates, and retail signage. Acrylic is lightweight, durable, and resistant to moisture, making it suitable for both indoor and outdoor applications.

Metal: Durable and Professional

Metal engraving is perfect for industrial tags, identification plates, tools, and premium gifts. Stainless steel and anodized aluminum are frequently used because they produce sharp, permanent markings.

Laser engraving on metal offers high durability, ensuring that text and logos remain legible even in demanding environments. Businesses often combine engraved metal components with custom printing services for cohesive branding solutions.

Glass: Elegant and Refined

Glass engraving delivers a sophisticated, etched appearance ideal for awards, wine glasses, and commemorative pieces. The laser creates a subtle frosted effect without compromising structural integrity.

Precision is essential when engraving glass, as improper settings can cause cracking. Working with experienced professionals helps maintain both quality and safety.

Choosing the Right Material for Your Project

Selecting the best material depends on your design, budget, and intended use. Consider factors such as durability, exposure to elements, desired aesthetic, and production volume. For example, metal is best for industrial environments, while wood or acrylic may be ideal for promotional or decorative applications.

For businesses creating planners, branded materials, or bound products, combining engraving with spiral coil binding solutions can elevate the final presentation.

Achieve Professional Results Every Time

Laser engraving offers precision, permanence, and versatility across multiple materials. By selecting the right surface and working with experienced professionals, you ensure your custom project meets both aesthetic and functional goals.

Whether you’re producing corporate gifts, industrial labels, or personalized keepsakes, choosing the right material is the first step toward a polished, lasting impression.